Tag: SDT

Mechanical Equipment, where Ultrasound Comes Into its own

Recently, the maintenance team at a mill in north-west France shared with SDT an unusual but crucial piece of feedback on mechanical fault detection...

Long Gone are the Days of Time-Based Lubrication

Lubrication management is a cornerstone of industrial maintenance, encompassing a range of tasks far beyond the simple application of oil or grease to machines.

It...

The Future of Industrial Lubrication: How SDT’s Ultrasound Technology is Revolutionizing...

Introduction

In the world of industrial manufacturing, the importance of lubrication cannot be overstated. From radial and axial bearings to complex gearboxes, lubrication plays a...

Bearing Grease Management using Ultrasound

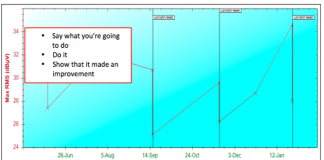

Inspection Technique

Greasing of bearings using ultrasound, often described as best practice, helps us understand how much grease needs to be applied. Ultrasound is...

The Parallel Paths of Maintenance and Lubrication

By Tom Murphy, C.Eng. CRL - SDT International

For maintenance programs, the decades-long migration from Breakdown to Planned to Predictive strategies represents significant, albeit slow-paced,...

Ultrasound Solutions for Industrial Predictive Maintenance and Quality Control

SDT provides ultrasound solutions that give our customers a better understanding about the health of their factory. We help them predict failures, control energy...

How to Use Ultrasound to Upgrade Lubrication Practicies

Avoid these 3 mistakes when lubricating bearings

Friction is all around us. Without it we would find it very difficult to run, walk, or even...

Bearing Monitoring using Ultrasound

In an ever changing world, most fundamentals remain the same. Take for example the rolling element bearing. Modern industry revolves around the bearing every...