Schaeffler at the Hannover Messe 2015 (Hall 22, Booth A12)

X-life is the seal of quality for particularly high-performance products from the INA and FAG brands.

Considerable potential for increased load capacity, longer life and greater power density is being released thanks to continuous development of rolling bearings, plain bearings and linear guidance systems. Functionality, economy and reliability can therefore be significantly improved in industrial applications. X-life is the seal of quality used by Schaeffler for products which have a considerably longer rating and operating life due to their increased basic dynamic load ratings in applications where the load and design envelope are identical. Where current basic load ratings meet user demands, X-life bearings allow designs to be optimized by using smaller bearings which save space and therefore reduce mass. Schaeffler is continuously expanding its catalog range through the addition of new, performance-optimized X-life products that allow customers’ requirements to be fulfilled and the overall efficiency of machines and equipment to be increased.

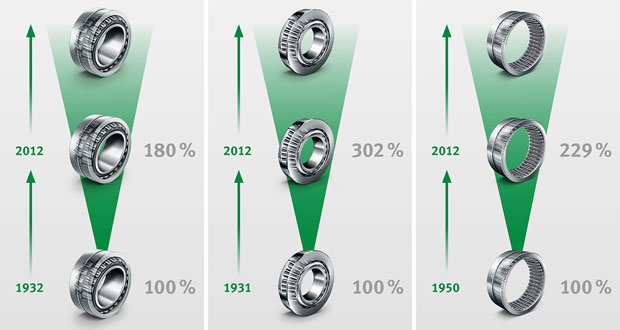

Over the last few decades, the ongoing technical development of rolling bearings (left to right: spherical roller, tapered roller, and machined needle roller bearings) has led to a significant increase in their dynamic load ratings.

Choose “Total Cost of Ownership”, high performance and energy efficiency

Users of rolling bearings are increasingly aware that the purchase price of a bearing is only one of many criteria to consider when deciding on a bearing. Rating life and service requirements as well as possible bearing failure must now also be taken into consideration. What does this mean in practice? More and more frequently, users are choosing higher quality rolling bearings with longer rating and operating life, extended maintenance cycles and increased reliability. Machinery fitted with long-lasting rolling bearings have a competitive advantage.

Schaeffler is presenting a new bearing type at the 2015 Hannover Messe with its FAG TORB toroidal roller bearing in X-life quality.

At the same time, the footprint of machinery is becoming an increasingly important factor in investment decision-making for many users today. From a manufacturer’s point of view, a compact design improves machinery’s competitiveness. The power density of generations of machinery has increased under similar or even increased performance requirements. This results in increased stress on components, including drive components, and therefore on the rolling bearings as well. These components are therefore being designed with an increasing degree of precision for reasons of space and cost. There is decreasing room for maneuver with respect to performance capability and it is therefore all the more important to use proven, high-performance drive components.

The desire for increased energy efficiency is still a key development priority for many users. Many manufacturing businesses have targets for reducing the energy consumed by production. A growing focus on efficiency classes for electric motors (“IE”) and other energy efficiency labeling make this an increasingly important factor. Rolling bearings optimize energy usage or efficiency in drives by managing friction. It is therefore obvious that users want low-friction rolling bearings.

Details in design that improve overall cost-effectiveness

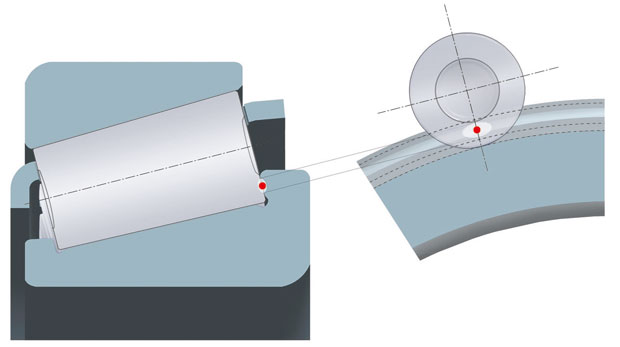

FAG tapered roller bearing in X-life quality: Optimized contact geometry between the rolling element end face and inner ring rib allows power loss to be significantly reduced.

X-life quality rolling bearings, plain bearings and linear guidance systems are matching trends in drive technology. Under the same operating conditions, the operating life of X-life bearings is significantly longer or, alternatively, higher loads can be applied while maintaining the same rating life values. State-of-the-art manufacturing technologies enable a better, more uniform surface over the whole contact surface between the rolling elements and raceway. The internal construction is designed for optimum functionality using state-of-the-art analysis and evaluation methodology and ensures optimized contact surface geometry and more uniform internal load distribution within the bearing. As a result, there is a reduction in the stress conditions present on the rolling elements and mating track under identical load. This produces a higher dynamic load rating, a longer nominal rating life, less friction, and lower bearing temperatures as well as a reduction in the strain placed on the lubricant. Research has proved that optimizing bearing positions with X-life bearings allows the overall cost-effectiveness of the relevant application to be improved.

This is made possible by, for example, the development of new steels which have fewer non-metallic inclusions and are optimized to specific operating conditions. Rolling bearing performance is further optimized as a result of using powerful calculation and design tools, for example Bearinx, which Schaeffler uses in the development of individual bearing types and series of bearings.

Continuous further development

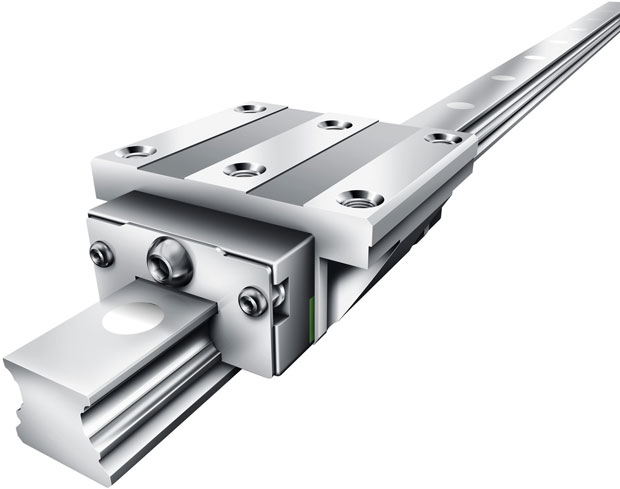

High-speed four-row linear recirculating ball bearing and guideway assembly in X-life quality. This high speed monorail guidance system KUVE-B-HS from INA Linear Technology is ideally suited to the high demands made on linear guidance systems in terms of speed and acceleration in, for example, textile machines.

The first X-life bearings were produced in 2003. Since then, an intensive program of further development has been implemented for nearly all bearing types which has allowed them to be included in the X-life range due to their increased dynamic load ratings. Proven X-life quality series include FAG axial and radial spherical roller bearings, FAG tapered roller bearings, FAG angular contact ball bearings, FAG and INA cylindrical roller bearings as well as INA radial insert ball bearing and housing units, INA machined needle roller bearings and INA axial angular contact ball bearings for wind turbines. On the linear side, INA linear recirculating ball and roller bearing and guideway assemblies as well as hydrostatic compact guidance systems are being produced in X-life quality. X-life large spherical plain bearings with ECOGLIDE are also available in the plain bearing range.

Schaeffler is presenting a new bearing design at the 2015 Hannover Messe with its FAG TORB toroidal roller bearing. This is an X-life roller bearing with angular adjustment. This single row rolling bearing has long, slightly spherical rollers. It thus combines the angular adjustment capabilities of a spherical roller bearing with the axial displacement of a cylindrical or needle roller bearing.

***

Schaeffler, with its product brands INA, LuK and FAG, is a leading global automotive and industrial supplier. The technology company stands for the highest quality and strong innovative ability. The Schaeffler Group makes a decisive contribution to the “mobility for tomorrow” with high-precision components and systems in engine, transmission and chassis applications as well as rolling bearing solutions for a large number of industrial applications. The company generated sales of approximately 11.2 billion Euros in 2013. With more than 80,000 employees worldwide, Schaeffler is one of Europe’s largest industrial companies in family ownership. It has a worldwide network of manufacturing locations, research and development facilities, sales companies, and training centers at approximately 170 locations in 49 countries.

The Industrial division supplies components and systems for around 60 industrial sectors via its worldwide organization and its application support service. The range comprises products from miniature bearings only a few millimeters wide to large-size bearings with an outside diameter of several meters.

Contact:

Martin Adelhardt

Schaeffler AG

Vice President Communication & Marketing Industrial Georg-Schaefer-Strasse 30

97421 Schweinfurt, Germany

Tel: +49 9721 91-3400

Fax: +49 9721 91-3375

[email protected]

Johanna Katzenberger

Schaeffler Technologies AG & Co. KG

Communication Industrial Georg-Schaefer-Strasse 30

97421 Schweinfurt, Germany

Phone: +49 9721 91-3873

Fax Phone: +49 9721 91-3375

Cell Phone: +49 151 4066 5844

[email protected]